TB/T1495.2-1992 "bullet I fastener"

GB/T 16491-2008 "electronic universal testing machine"

GB/ t12160-2002 "specification for single shaft test"

GB/ t16825-1997 test of tensile testing machine for verification and acceptance.

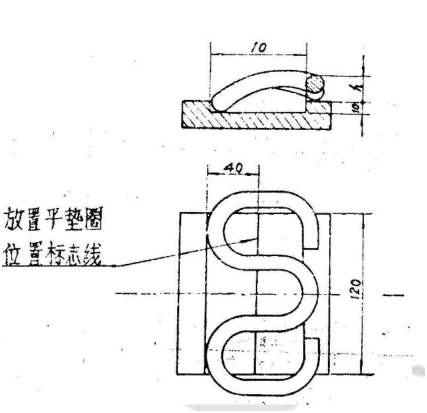

Article 1, will play on the platform, in front of the depth measurement plays a central relative height, remember to h0, then bounce in characteristics of tire type, as shown in the figure below, and the tire model on the pedestal machine;

2 draw a line, place the position of the washer on bounce, the testing machine between head and play the mat a Φ 50 mm flat washer (thickness is not less than 6 mm, hardness HR41-47), make the center line of the washer and the mark line overlap;

3. Slowly load to 50KN and stabilize 5s, then unload back to zero.After repeated three times, put the spline back on the platform, and at the front of the measurement, the relative height is recorded as h1, and the residual deformation of the elastic strip is h0-h1.

1. Style: double column door type.

2. Test force: 100KN.

3. Range: 2% to 100%;

4. Test force accuracy;Plus or minus 1%

5. Accuracy of test force;0.01 KN

6. Test machine level: level 1.

7. Displacement resolution: 0.01mm;

8. Accuracy of displacement measurement:

9. Stretch stroke: 600mm (customizable)

10. Compression stroke: 600mm (customizable)

11. Control range of displacement velocity: 0.1mm/min ~ 300mm/min.

12. Accuracy of displacement velocity control:

13. Size of the test machine: about 720mm, 500mm and 1780mm.

14. Test machine weight: about 450KG.

15. Appearance: should comply with GB/T2611 requirements.

16. Completeness: meet the standard requirements.

17. Protection function: the testing machine has overload protection function.

18. Power supply: 220V, 50Hz.

Copyright 2010-2017 siyuan. All Right Reserved备案号:鲁ICP备14010418号-12