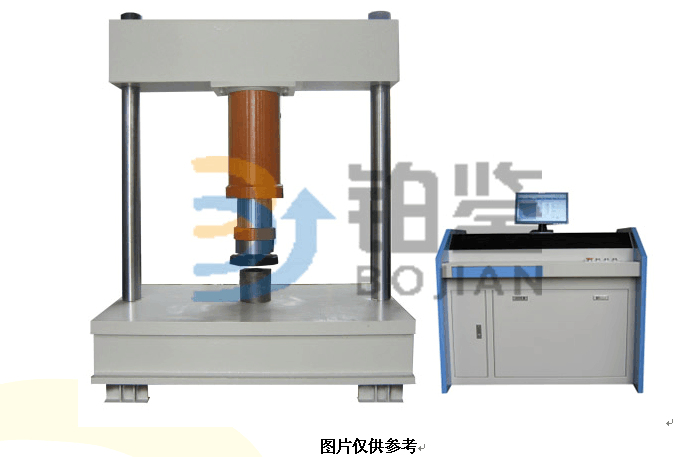

The microcomputer controlled electro-hydraulic servo manhole cover pressure tester is mainly used for residual deformation and compressive strength test of manhole covers. The test machine adopts advanced technology such as servo valve of wide speed range and computer digital control. It can automatically and accurately measure and control the whole process of test machine loading, unloading and so on. All kinds of test parameters are controlled, measured, displayed, processed and printed by computer, with high integration and convenient operation.

GB/T23858-2009 "check the cover of the well"

CJ/T121-2000 "recycled resin composite inspection manhole cover"

JC889-2001 "steel fiber concrete inspection well cover"

GT/T2611-2007 "general technical conditions for testing machines"

JJF1103-2003 universal testing machine computer data acquisition system evaluation.

1. The main engine adopts a high rigidity structure to ensure the safety during the test.

2, loading the oil cylinder on the table, the height of the table 360mm, easy to take the manhole cover test piece.

3, the ball block joint between the rigid pad and the piston pushing end ensures that the contact between the manhole cover and the reaction plate is complete, so as to ensure the authenticity of the bearing capacity.

4, oil cylinder and piston are sealed by special materials to achieve high sealing, low friction and long life.

5, professional test engine oil pump motor group, low noise and long life.

6. Choose super precision oil filter to ensure cleanliness in the oil circuit system so as to ensure the long term work of controlling the execution components.

7, computer automatic control, real-time display of current force value, peak value, deformation, test process information and so on.

8. The test process records the test curve in real time and sampling at high speed.

9. The processing function of data and report provides the user with a special report editing tool for graphic typesetting. It has the characteristics of flexible operation and easy to learn, and can easily print test curves and test values.

10. The control mode has the control function of isokinetic stress, isokinetic test force, test force retention and other control functions as well as test force, the screen display function of peak, piston displacement and test curve. The test curve is powerful time curve, force deformation curve, deformation time curve, and control mode smooth conversion.

11. According to the needs of the experiment, the user is programmed by itself, automatic closed loop control, cyclic loading, loading speed and loading waveform. (because the standard loading process is a cyclic waveform loading process), every index step of the national standard can be programmed to make the whole process complete the whole process without manual intervention. Automation.

1. Maximum test force: 1000KN

2. Effective test space: 1200mm x 1200mm (with 1500*1500mm section).

3. The height of the workbench: 350mm

4, force value accuracy: less than + 1% (better than 1 level).

5. Loading speed adjustment range: 0.1 ~ 25KN/s (automatic stepless speed regulation).

6, piston stroke: 500mm

7. The effective range of the test machine: 2%-100%FS

8. The precision of the compression deformation measurement: less than 0.01mm

9, rigid adjustment pad size: 356mm, 250 x250 X150 mm,

250 x250 x75 mm 1 pieces

10, lower worktable size: two column effective width 1200mm, worktable distance 1200mm

11, the load indication precision: 0.1KN

12. Loading mode: electrohydraulic

13, control mode: microcomputer controlled stepless speed regulation, with on-site programming function.

14, loading medium: 46#, 68# antiwear hydraulic oil.

15. Motor power: 2.2KW

16. Demand voltage: 220V

17, host size: About 1450mm * 1200mm * 1950mm (long * width * height)

Control cabinet size: about 1260*950*1050

18. The weight of the host: more than 3300Kg

19. Overload protection point: over full range 3% automatic unloading.

Copyright 2010-2017 siyuan. All Right Reserved备案号:鲁ICP备14010418号-12