Hardness is an important indicator of mechanical properties. It is the ability of a material to resist another hard object with a certain shape and size, and it does not have the residual deformation in itself.

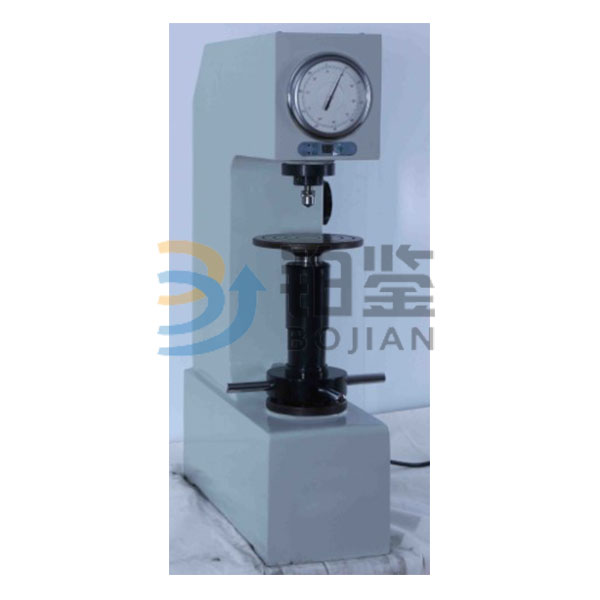

Rockwell hardness test is the fastest, the simplest and the most economical test method in the mechanical performance test. It is not only simple in operation and high in efficiency, but also can obtain experimental results directly. With the rapid development of industry in China, Rockwell hardness test has been widely applied.

The scope of application of common Rulers:

A scale: it is suitable for testing thin plate material or surface layer, and also for hardness testing of 70HRC, such as cemented carbide.

B scale: it is suitable for non-ferrous metals and their alloys and annealed steels with low hardness. The test range is 20 to 100HRB.

C scale: suitable for hardness test of steel specimens after heat treatment. The test range is from 20 to 70HRC.

The initial test force of 3.1: 98.07N (10kgf)

3.2 total test power: 588.4N (60kgf) 980.7N (100kgf) 1.471KN (150kgf)

3.3 indicator scale: C:0 ~ 100 B:30 ~ 130

3.4 the maximum distance between the center of the indentation and the wall of the machine: 130mm

3.5 the maximum height of the test piece: 170mm

3.6 hardness meter size 457 x 240 x 629mm

3.7 the net weight of the hardness meter: 75kg

Copyright 2010-2017 siyuan. All Right Reserved备案号:鲁ICP备14010418号-12